Development of some mechatronic systems

Development of Surface Finishing Process-Ball Burnishing Process

Ball burnishing process is one of the surface finishing processes, which results in a plastic deformation on the workpiece surface by using a steel ball or a roller, to improve the surface roughness, surface hardness, and fatigue resistance.

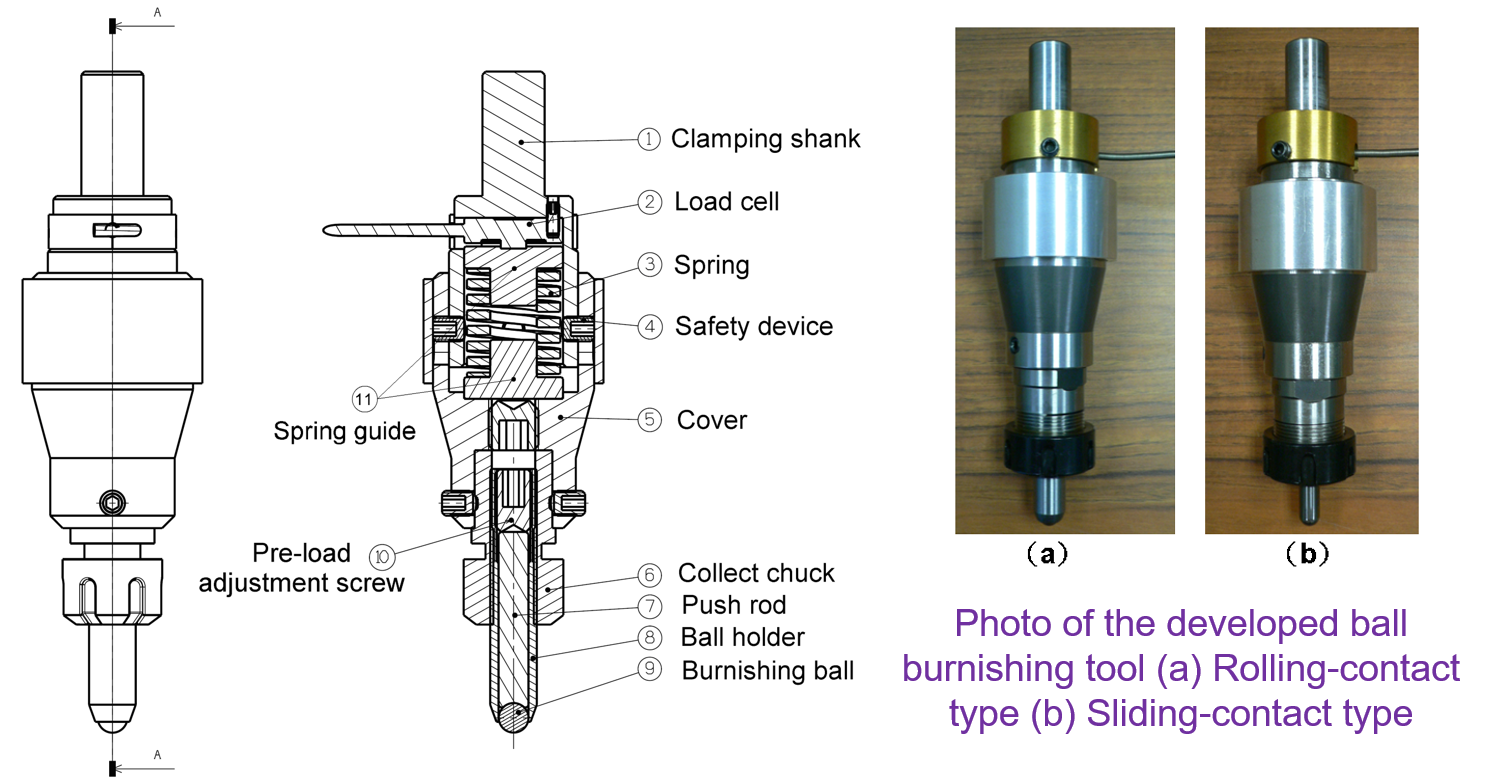

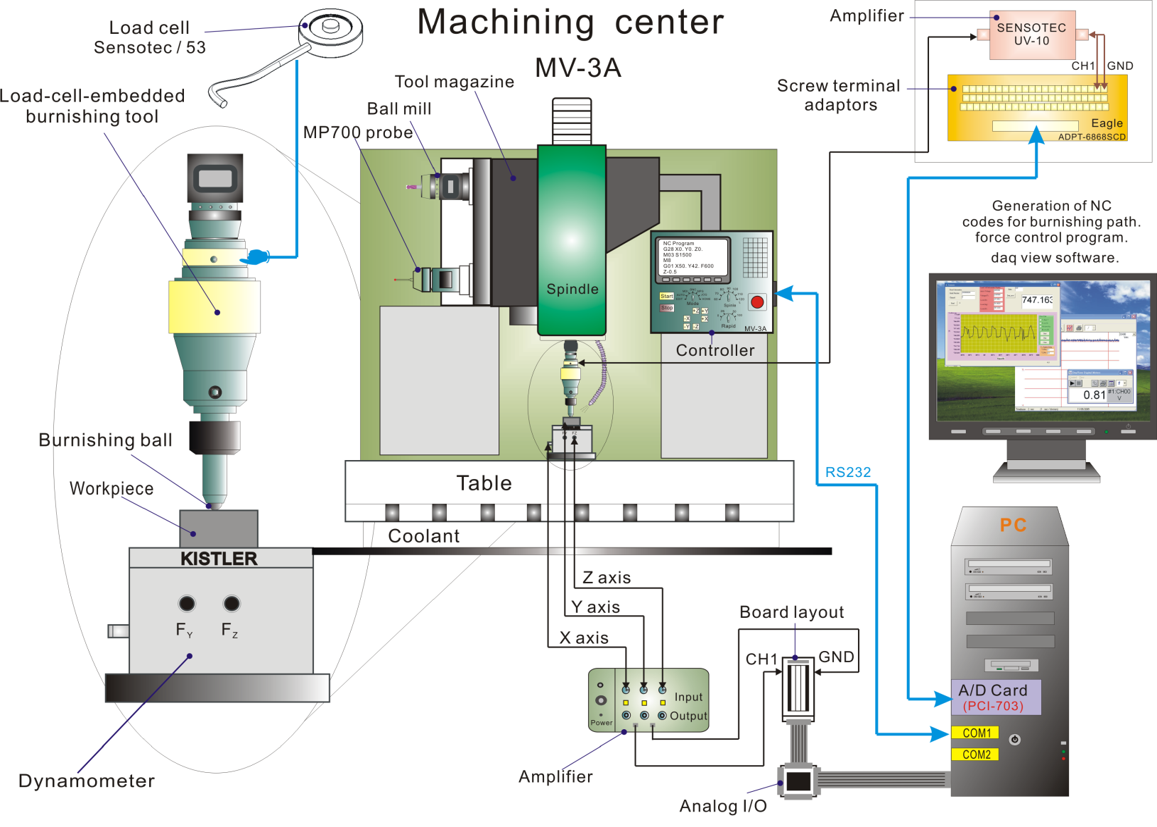

Development of Surface Finishing Process-Designed Ball Burnishing Tool for a Machining Center

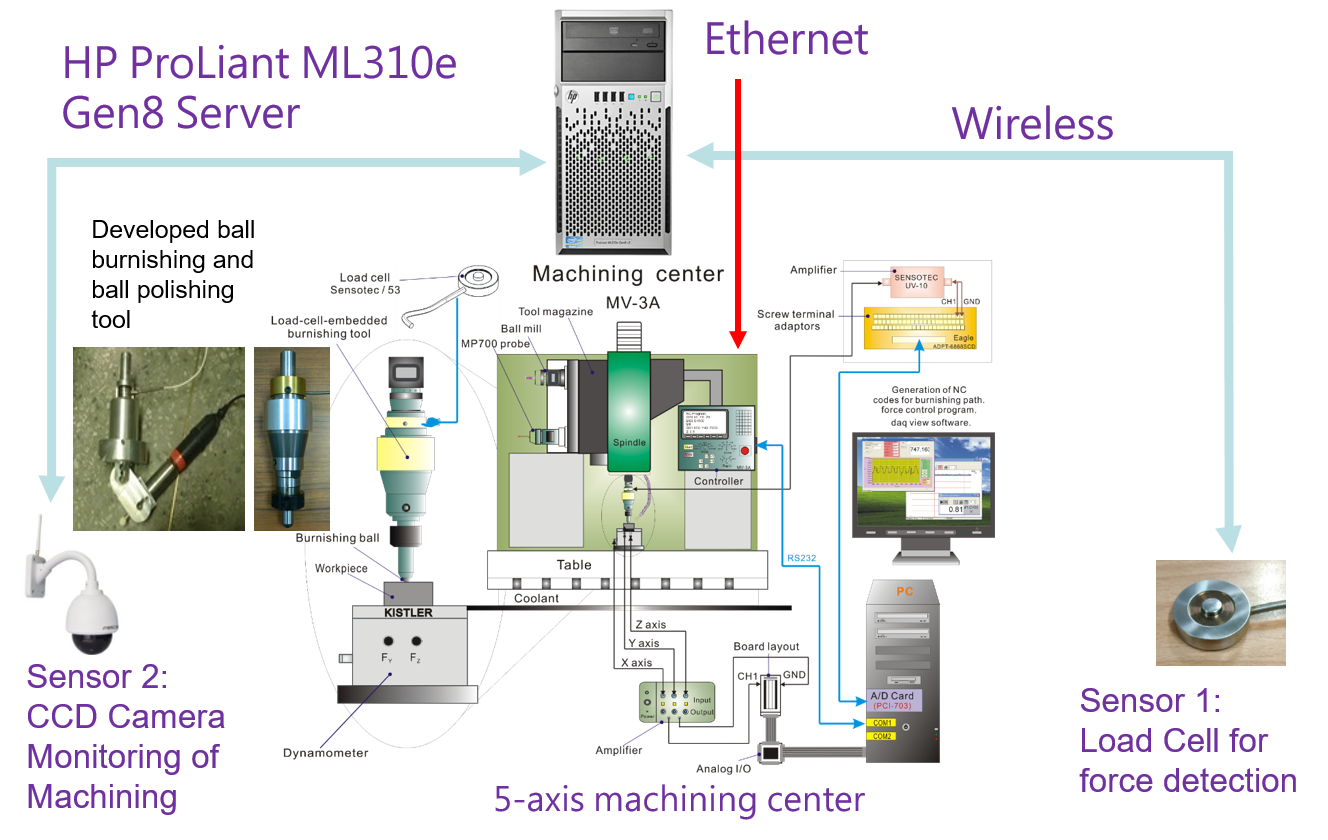

Development of Surface Finishing Process-Experimental Setup of Ball Burnishing Process

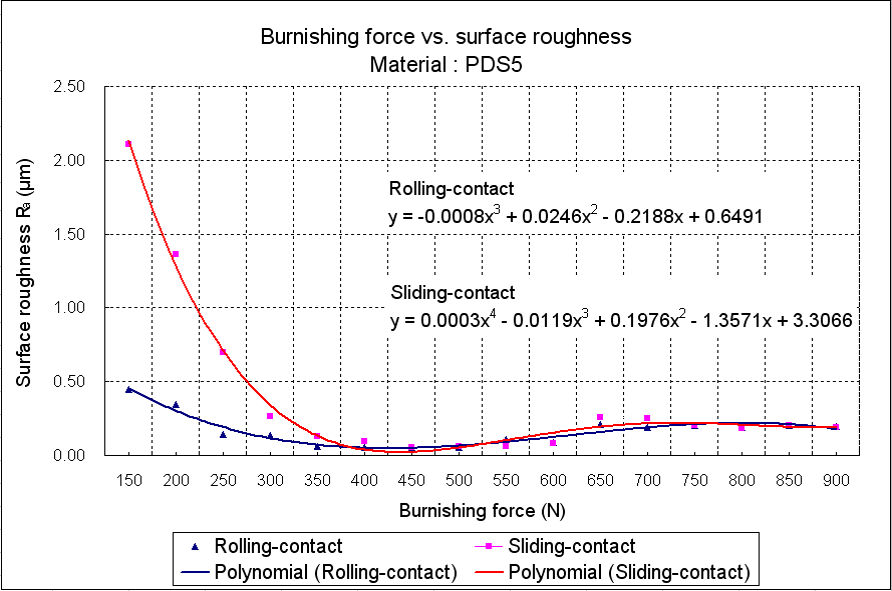

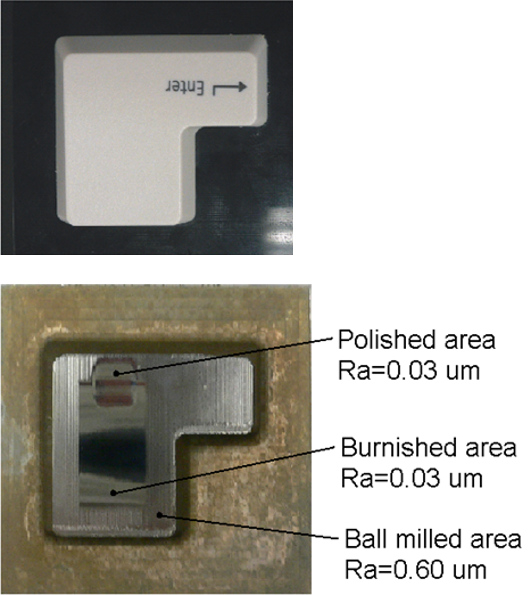

Development of Surface Finishing Process-Results of Ball Burnishing Process for a Tool Steel

Innovative Application of Advanced CPS to Precision Ball Burnishing Process

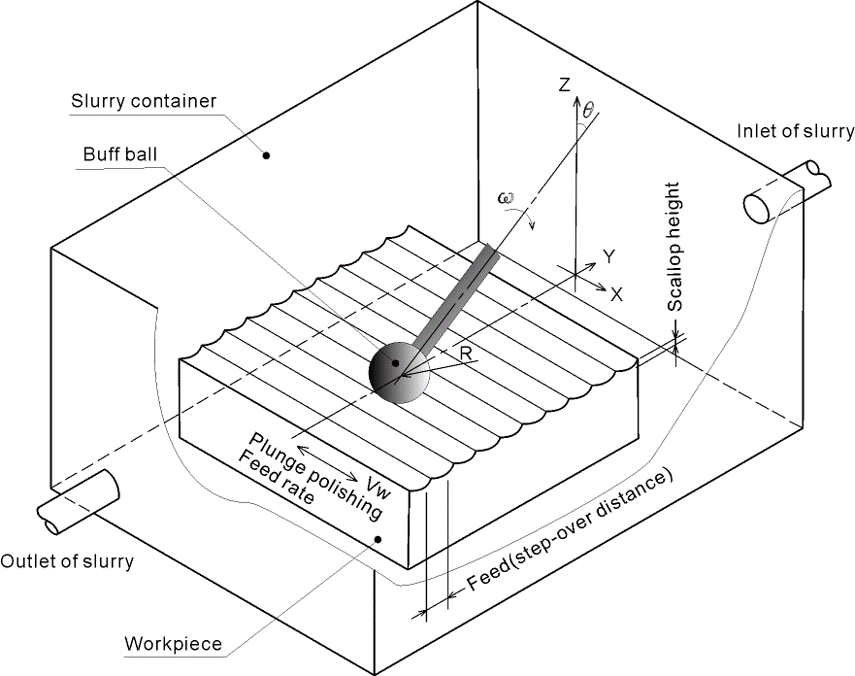

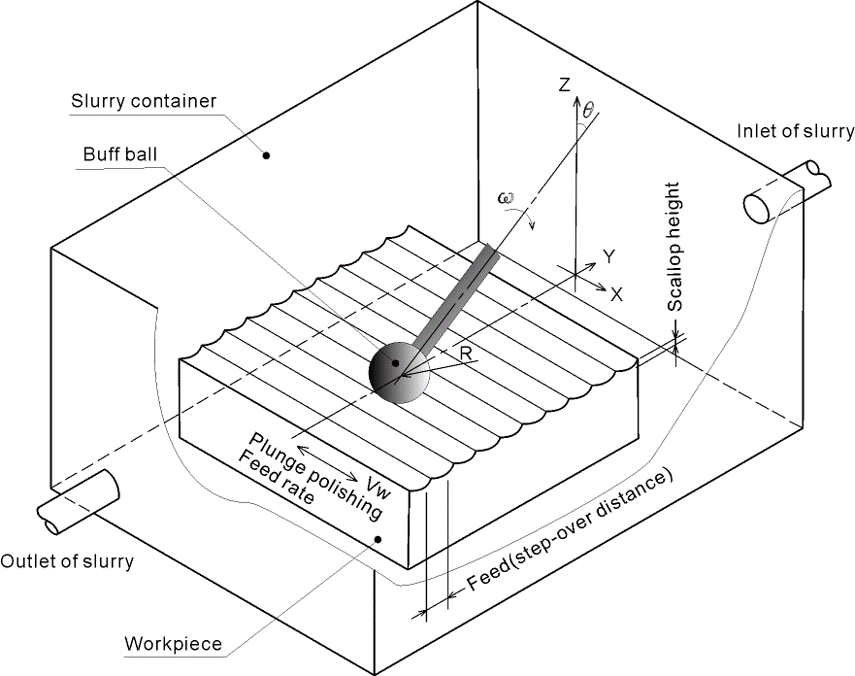

Development of Surface Finishing Process-Ball Polishing Process

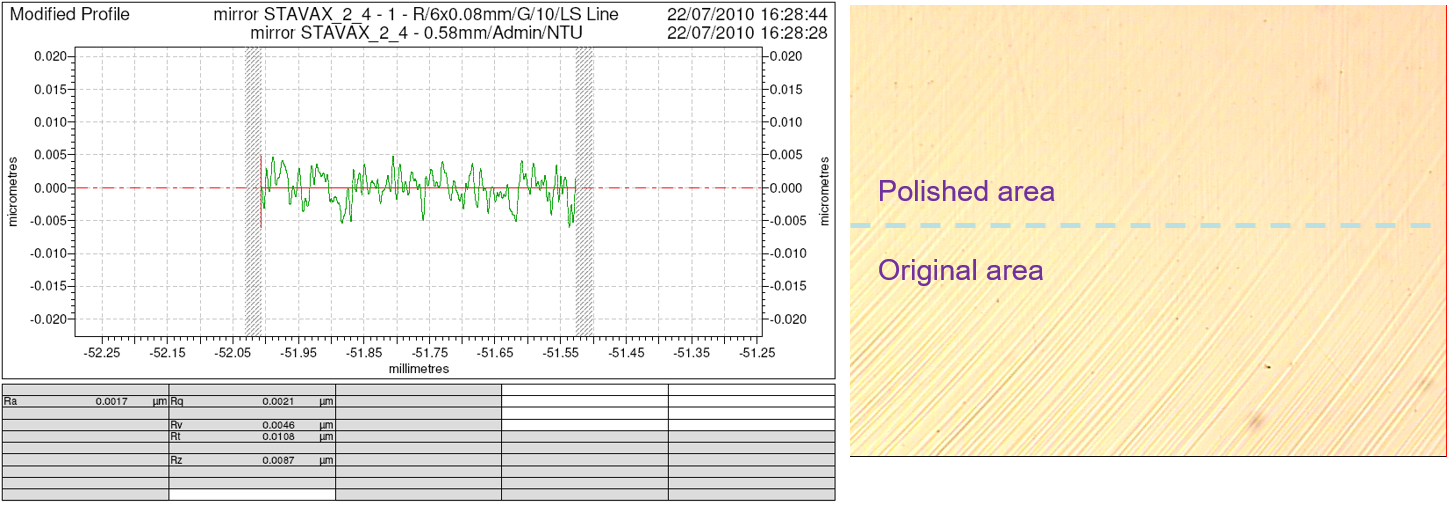

The surface roughness was improved from Ra 9.8 nm to Ra 1.7 nm with the film thickness of 8 um.

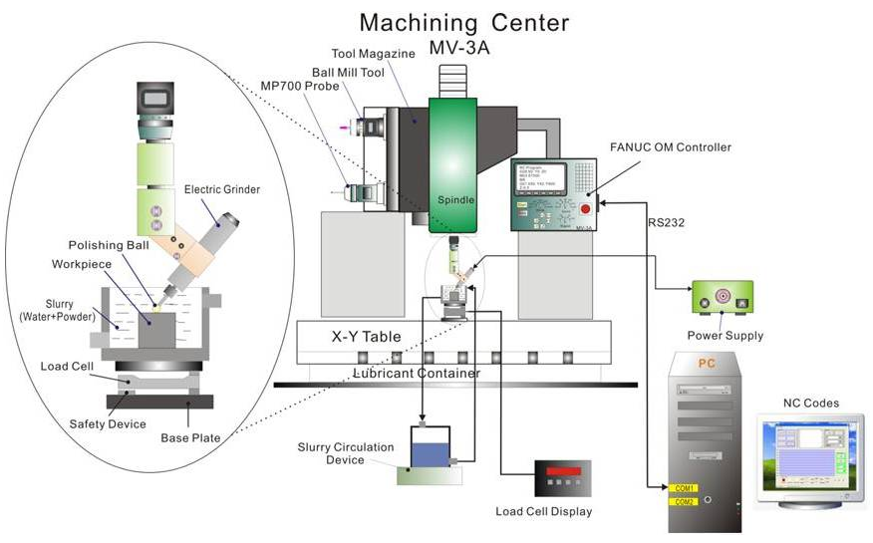

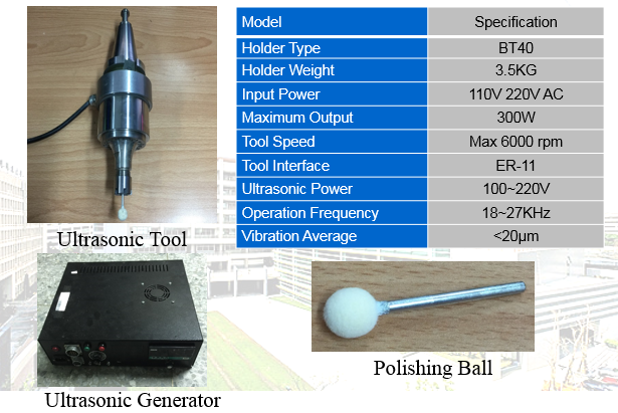

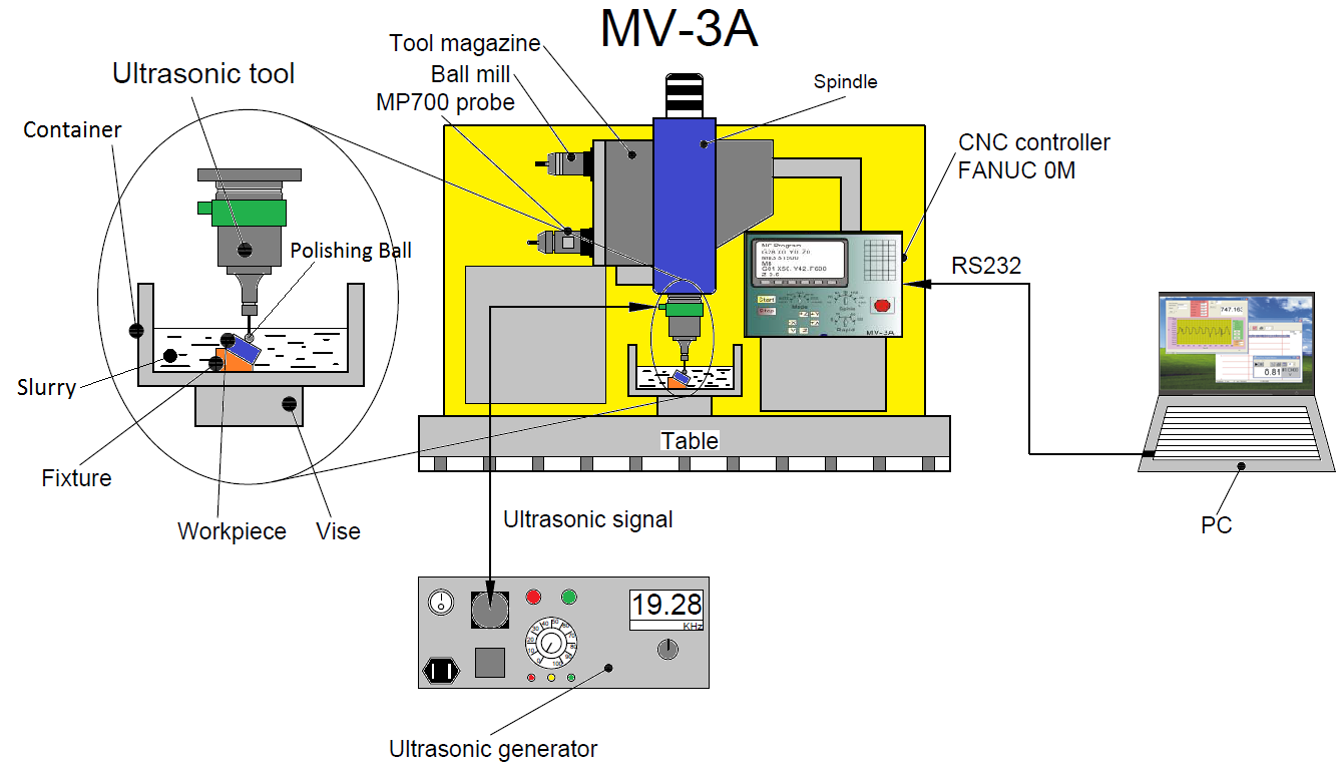

Development of Surface Finishing Process-Ultrasonic-Assisted Ball Polishing Process

Development of Surface Finishing Process-Photo of the Ultrasonic-Assisted Ball Polishing System

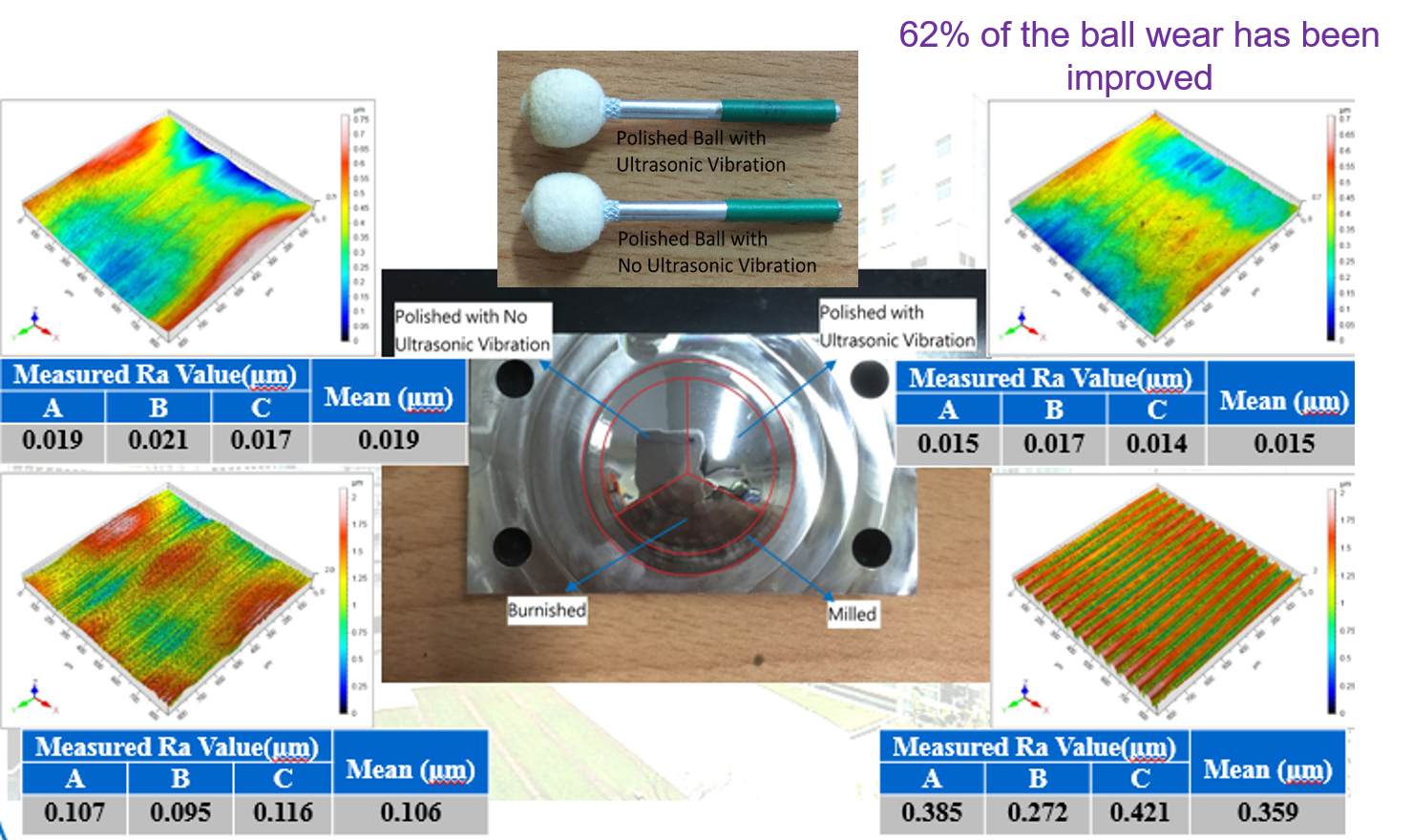

Application of the Ultrasonic-assisted Ball Polishing to a Mould Steel

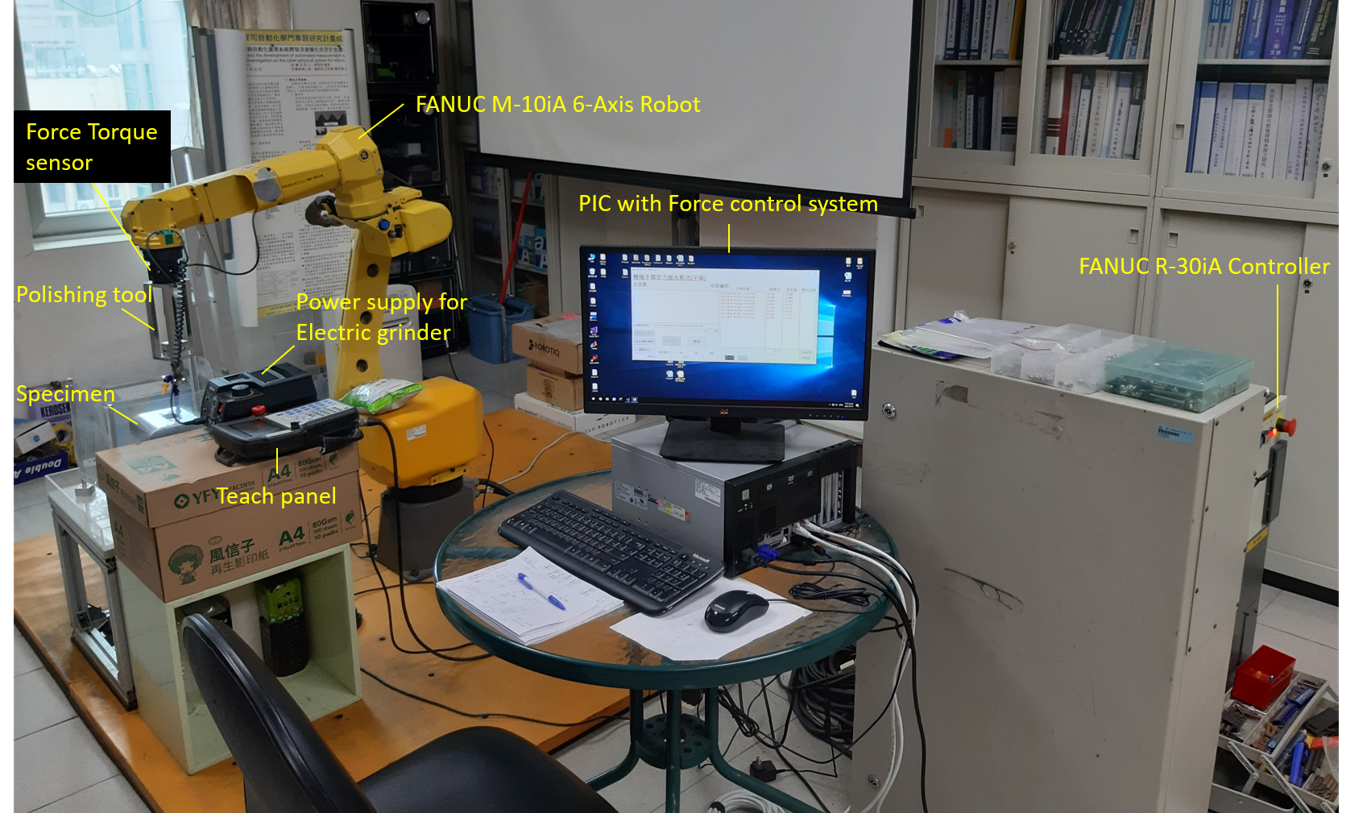

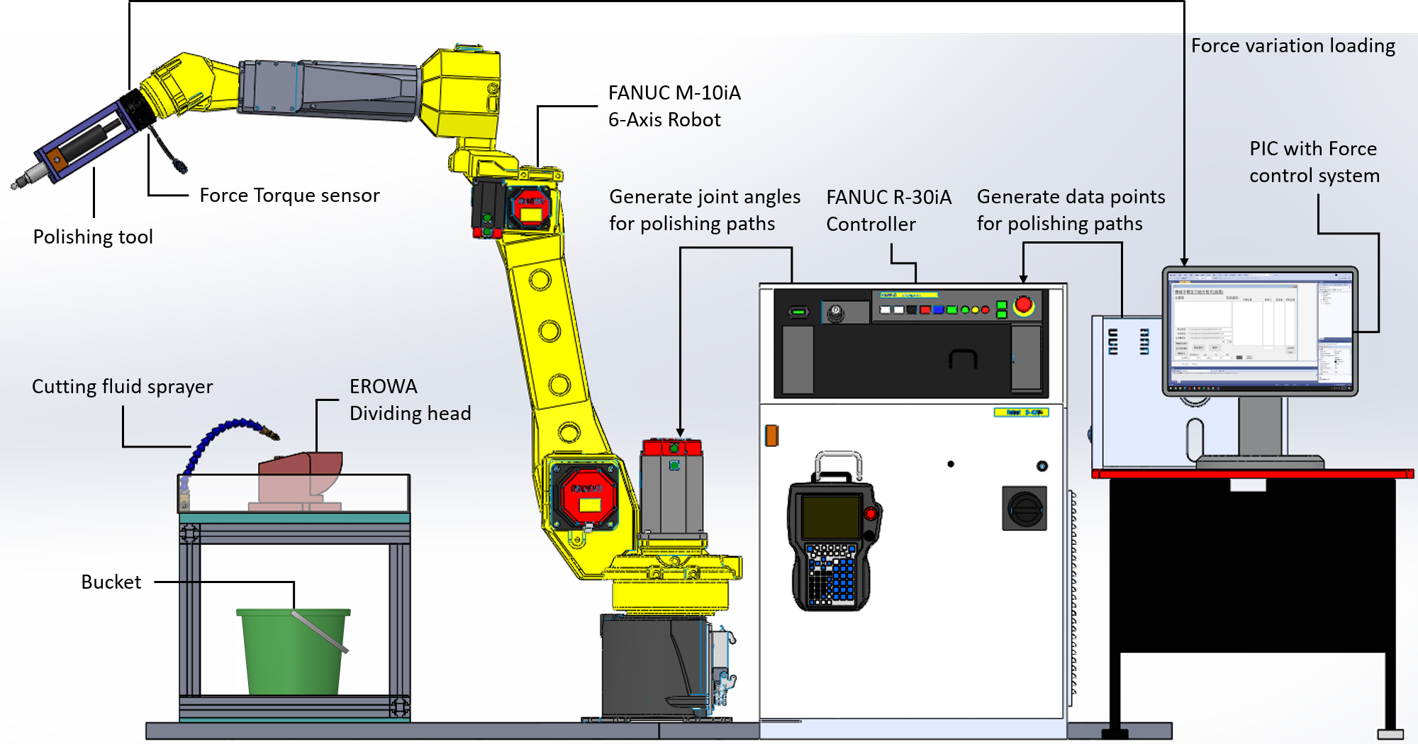

Development of a Robot Assisted Polishing System

Photo of the Robot Assisted Polishing System